One of the major advantages of using a cattle ultrasound machine for backfat eye area testing is that it is non-invasive and relatively stress-free for the animal. In addition to equipment commonly found on farms or ranches and in clinics, the scanning operation does not require special handling equipment for the animals. In order to reduce stress on the animal and minimize the chance of injury to both animal and operator, most people find that the best location for the scanning operation is the livestock crush chute or squeeze.

The animal should be moved to the chute or crush with as little stress as possible. The head should be securely fastened in the headgate and checked to ensure that there is enough freedom not to cause suffocation or any other type of injury to the animal. Once the operator has safely immobilized the animal, any of the previously described scanning operations can be performed, including backfat, rump fat, loin eye area, and muscle mass characteristics. Restrained beef cattle were scanned for the 12th and 13th ribs and rump area.

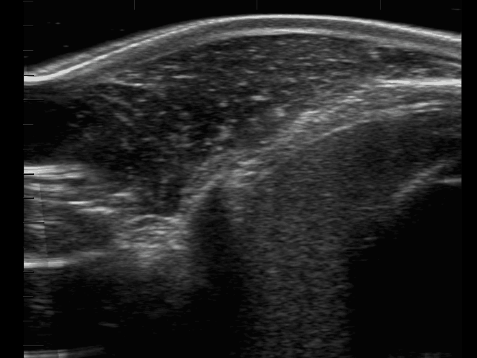

Site preparation was similar for all scanning operations. To obtain good acoustic contact, some operators prefer to cut the hair in the area prior to scanning. While this may be ideal for scanning purposes, it may not always be practical (i.e., time constraints, showing or displaying cattle, sorting feedlot cattle). If the scanning area is not trimmed, the operator can improve image quality by using a brush or metal comb to ensure removal of loose hair and dirt. Veterinary ultrasound technicians/operators are well aware of the need for good acoustic contact between the probe and the skin surface, as sound waves do not travel through the air. Human applications use scanning gels for acoustic contact, however, scanning beef cattle using gels can be expensive and impractical as it is difficult to get the gel into the fur without air pockets. Therefore, food animal scanning requires the use of vegetable oil. This coupling agent is readily available, inexpensive, and harmless to the animal, operator, or probe. (Mineral oil should never be used as it is harmful to the probe surface and cables). Since most scanning operations are performed outdoors under less than ideal environmental conditions, oil temperature may affect image quality. Clear results are obtained when the oil temperature is close to 27°C. This keeps the oil free-flowing. This keeps the oil free-flowing and allows better penetration into the hair.

By looking at the linear array probe, it is clear that some type of adaptation is necessary for cross-sectional scanning of the lumbar eye muscle region. Therefore, acoustic contacts are available as an accessory to each unit, and contacts of varying curvature can be used for beef or pig scans. The contacts are easily attached to the probe and a small amount of scanning gel is used to ensure integrity. Palpation of the scanning site and application of acoustic coupler (vegetable oil). Thermoelectric heating and cooling devices applied to maintain the scanning oil affect image quality, especially in cold climates. Best results are obtained when the contact pads and acoustic gel are also maintained near the temperature of the oil. Pads should be cleaned with warm soap and water after each use and stored in a suitable container to prevent damage and drying of the flexible material. If cared for and stored as recommended, the pads should last indefinitely.

Post time: Jan-22-2024